Hot and Cold

UC Davis engineers are innovating at high and low temperatures to enable travel at hypersonic speeds and sustainably keep food safe and fresh, respectively.

HOT

Materials Science and Engineering Assistant Professor Scott McCormack grew up in a small fishing village on the sapphire coast of Australia, where his high school dream of working for NASA seemed far-fetched to some of his teachers. However, he kept this dream alive. Now his lab studies materials that melt at temperatures as high as 4000°C (7232°F) and can withstand the extreme heat loads necessary for building space and hypersonic vehicles.

“I strove to study high-temperature materials because I knew that would have an application for space exploration,” he said.

(Josh Moy/UC Davis)

McCormack received a National Science Foundation Faculty Early Career Development Program (CAREER) Award in 2021. His project addresses the lack of thermodynamic data for ultra-high temperature, multi-component materials in ceramic engineering. These materials’ properties and melting temperature can be controlled by adding different elements, or components, to the system. It’s possible to measure these materials’ properties at ultra-high temperatures, but it’s much more difficult, so there is nowhere near as much data.

“This makes it difficult to engineer advanced and tailorable high-temperature ceramic systems because we don’t have the fundamental multi-component thermodynamic data to drive design,” he said.

McCormack’s solution is filling in phase diagrams for these materials, charts of properties at different temperatures and pressures. His group identifies parts of the phase diagrams with the greatest amount of uncertainty and conducts experiments to fill in the gaps with accurate data and get a better picture of the properties.

“It’s like using a plane to look over the forest to broadly identify the different types of trees before you target each tree individually,” he explained.

If successful, McCormack hopes this method can be applied to other material systems to collect thermodynamic data faster.

Though most of the group’s work is at low technology readiness levels (TRL), where the materials are still being explored, it has recently started moving in a more applied direction. With a recent $1.4M grant from the Air Force Office of Science and Research, the lab and its collaborators at Missouri University of Science and Technology and the University of Pittsburgh are studying how to process ultra-high temperature ceramics (UHTCs) reliably.

“Different labs will follow what they think is the same procedure, but the UHTC components have quite a high variability in their properties,” he said.

The team will study the UHTC zirconium diboride (ZrB2) at each of its three processing stages to study how processing affects the material structure and resulting properties. They will then develop and validate a computer model that recommends the processing parameters required to produce UHTC components reliably. If successful, the project is the first step toward standardizing UHTC processing and making these materials available for building hypersonics and other high-temperature applications.

“The core goal of the project is to reduce uncertainty when processing ultra-high temperature ceramics,” he said. “We’re developing a recipe with bounds that will allow us to say, ‘this is the impurity-range/processing time/pressure you need to reduce uncertainty.’”

COLD

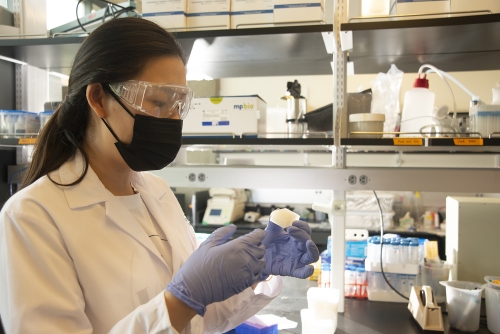

Researchers in Biological and Agricultural Engineering Professor Gang Sun’s lab have developed a plastic-free “jelly ice cube” that could revolutionize how food is kept cold and shipped fresh.

These plastic-free “jelly ice cubes” are alternatives to ice or traditional cooling packs that do not melt, are compostable and anti-microbial, and prevent cross-contamination.

“When ice melts, it’s not reusable,” said Gang Sun, a professor in the Department of Biological and Agricultural Engineering. “We thought we could make a so-called solid ice to serve as a cooling medium and be reusable.”

The cooling cubes contain more than 90% water and other components to retain and stabilize the structure. They are soft to the touch like a gelatin dessert and change color depending on temperature.

These reusable cubes can be designed or cut to any shape and size needed, said Jiahan Zou, a Ph.D. graduate student who has been working on the project for the past two years.

“You can use it for cooling, collect it, rinse it with water and put it in the freezer to freeze again for the next use,” Sun added.

A patent for the design and concept was filed in July.

The researchers hope to eventually use recycled agriculture waste or byproducts as the coolant material.

“We want to make sure this is sustainable,” said Luxin Wang, an associate professor in the Department of Food Science and Technology.

The researchers began working on the coolant cubes after Wang saw the amount of ice used at fish-processing plants and the cross-contamination that meltwater could spread among products or down the drain.

“The amount of ice used by these fish-processing sites is massive,” Wang said. “We need to control the pathogens.”

Sun also lamented mold found in the plastic ice packs used with school lunches for kids and frequently found in shipping packages.

Early tests have shown that the cubes can withstand up to 22 pounds without losing form. They can be reused a dozen times — just a quick wash with water or diluted bleach — and then disposed of in the trash or with yard waste.

The jelly ice cubes offer an alternative to traditional ice and could potentially reduce water consumption and environmental impact. They also offer stable temperatures to minimize food spoilage and could be ideal for meal prep companies, shipping businesses and food producers who need to keep items cold.

The application could potentially reduce water consumption and food waste by controlling microbial contaminations in the food supply chain.

This story was featured in the Spring 2022 issue of Engineering Progress.